One Drop Anniversary Project

Reviewed by Chris Rhoads

December 12, 2010

Introduction

Stop me if you have heard this one before. A man walks into a machine shop, sets a yo-yo on the counter and asks, “Can you make me one of those?” To most this would sound like the beginnings of a very odd joke, but those in the yo-yoing community know that this was how One Drop YoYos came into being. It started out with a player by the name of Colin Leland entering into a local Eugene, Oregon machine shop and asking the guys in charge, David and Shawn, to make him a metal yo-yo. The story goes that at first Shawn and David were a little apprehensive about making one due to the tools they had at the time, but curiosity got the better of them and the result was the now famous Project. This all happened back in November 2007 with the release to come several months later. During the time of inception and the actual release date David, Shawn, and Colin worked hard to refine every aspect of the yo-yos design. The diligent work speaks for itself, the Project went on to monumental success being praised by players the world over. To commemorate the yo-yo that started it all, One Drop has chosen to release a small run of Projects made using the same tools that were used to create the original. These Anniversary Projects are purposely kept indistinguishable from their original run brethren, right down to the packaging and lack of any marking denoting their anniversary status. This review is not an easy one for me to write. The Project was a huge success, but it is a three-year-old design and the tools used were an odd choice for the task at hand. Is this yo-yo still relevant in today’s modern era of throwing or are these anniversary releases more of a nostalgia piece than anything else?

Specs

Diameter: 50mm

Width: 40.2mm

Weight: 64 grams

Gap Width: 4.24mm

Stock Response: .555 Thin One Drop Silicone Pad

Bearing Size: One Drop 10 Ball Bearing

Construction

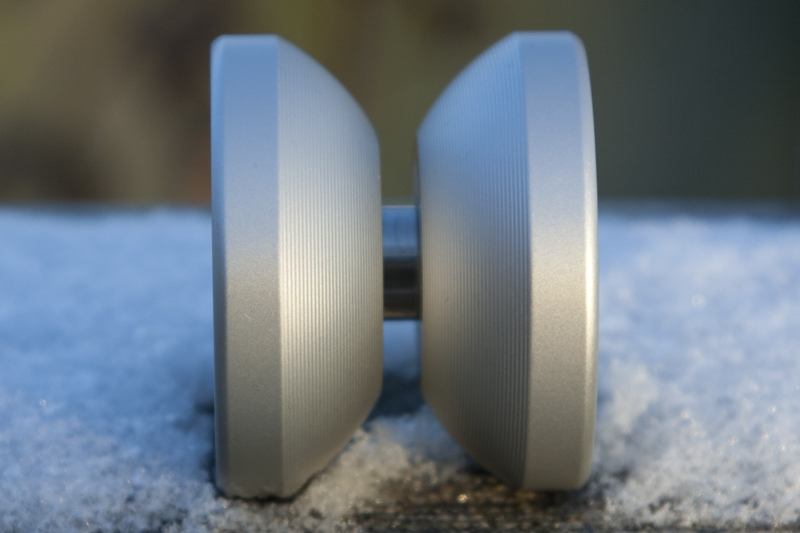

As I mentioned in the introduction, The Project was machined in an odd fashion for a round, spinning device. Normally a yo-yo is machined using a lathe, a tool that spins the slug of metal at a high rate of speed while cutting the shape into it. This keeps the yo-yo concentric allowing it to spin smoothly when completed. The Project was machined using a mill which lays the metal slug flat and cuts the shape of the yo-yo into it. The slightest miscalculation in programing can cause catastrophic results and give you a vibey, wobbly yo-yo that is completely unplayable. As David explained it to me “you don’t use a mill to make a round part”. In the end the mill worked out for them and it also gave the Project one of its most striking features, the projection profile. These grooves in the catch zone are actually the stair steps of the mill’s cutting tool as it moves from the rims up cutting in the curve of the catch zone into the yo-yo. This happy little machining quirk aided the yo-yos grind abilities and gave a truly unique look to the yo-yo. The catch zone transitions into a set of perfectly flat rims making the Project one of the earlier metal yo-yos to have a flat rim design. Moving to the cups of the yo-yo there is another set of grooves cut in tying the look from the catch zone with the profile of the yo-yo. In the center of the yo-yo we have what can only be described as the most iconic piece of One Drop design to date, the nut capture and hex nut axle system. The unique nut capture shape houses three rubber nibs that grab the edges of the hex nut and preventing parts explosion when disassembling the yo-yo. This complex nut capture system would not be needed if the One Drop team had not over engineered the axle system itself. Some have said that the guys solved a nonissue but I see it as a forward thinking design. Threading a steel axle into a softer aluminum body can cause the softer metal to fatigue over time, the solution as Shawn, David, and Colin saw it was to thread steel into steel by using hex nuts in the hubs. Any person who has stripped the threads out of an aluminum yo-yo, such as myself, can appreciate this little touch of over engineering. One Drop was not the first to use a hex nut axle system, but they were one of the first to not hide it under a set of caps, instead they embraced the industrial look that the nut gave the yo-yo. Finally, this would not be a Project review without mentioning the soda blast finish. As the name implies, this finish is attained by blasting the raw aluminum with baking soda. This gives the yo-yo a smooth, easy grinding finish. The added side effect of the soda blast finish is that, when coupled with a clear anodized coating, it gives the yo-yo as close to a white color as one can get without painting, powder coating, or total body laser etching. Over all the industrial design and near white finish of the yo-yo gives it a stand out look among the yo-yos of its day and still stands out when compared to even the most radical of designs today.

Weight

This is a light and speedy yo-yo on the string. It isn’t uncomfortably fast or anything but it does zip about on the string. The lightweight makes it quick to change direction when it is told to. The overall distribution of weight gives the Project a nice balance between spin time and stability with a good portion of the weight residing in the rims.

Response and Bearing

The response of the Project is probably the most “old school” part of the yo-yo. The thin .555 pads are a stark contrast to today’s recessed flowable silicone guts. I do prefer a more modern response. The pads in the Project took some extra breaking in to get it to play dead unresponsive and every so often it does catch the string causing the yo-yo to shoot back to the hand. This isn’t a huge knock against the Project since it was designed at a time when flowable silicone was not prevalent in the community.

Where the pads are a little dated, the bearing is pure modern magic. The Project was the yo-yo that introduced the world to the One Drop 10-Ball bearing and it has been a fan favorite ever since. The 10-Ball is quiet, smooth, and long spinning… everything that I look for in a bearing. It also has a long shelf life. I have yet to kill a 10-Ball and I put them in every yo-yo I keep for my collection.

Playability

Out of the box this yo-yo played slightly responsive due to the fresh set of pads. After breaking in the pads I put it through its paces and noticed a slight vibe in the yo-yo. Most people would see vibe and have to spend hours tuning it. This is not the case with the Project, there is a little secret in the design that makes tuning a painless, at most, five-minute process. All you do is crack open the yo-yo push the axle out and give it a small turn and push it back in to the nut capture. Repeat as necessary until the vibe is gone, in my case it took two turns to get a smooth playing yo-yo. Once tuned, the Project gave a very rewarding experience while throwing. It is easy to pull off pretty much any trick that you want. The catch zone is wide open and the gap will hold a decent amount of string. The soda blast finish and projection profile grinds exceptionally well on the palm, arm and finger. Thumb grinds take a little extra work due to the total lack of an IRG. Throwing the yo-yo at a slight angle corrects this issue. In the end I could not find a single trick that I could not pull off on this three-year-old yo-yo when compared to todays modern designs.

Final Thoughts

As I said above, this yo-yo review was hard to write. Not only did I have to worry about three years of history but I also had to tread lightly on the opinions that others have formed over those three years. In the end I took two approaches to writing this piece. Half of it is a history lesson on the Project and the company, and the other half is the review itself. When it comes to the viability of the Project when compared to today’s modern throws I would say that it definitely hold its own. It plays as good, if not better than most of the undersized yo-yos dropping on the market today. About the only change I would make to the Project is to redesign the guts to accept flowable silicone. In the three years that the Project has been out I have owned three of them. Even with the pad response, playing with the Project never gets old and has been in my daily rotation since I received my first one in a trade. If you are looking for a Project of your own you can easily find one in the buy, sell, trade section of your favorite forums. If you were hoping to pick up a new one then you are out of luck, this year’s lot sold out in 24 hours but don’t fret, November 2011 is only 11 months away.

For those of you that would like to know more about the history of this great yo-yo I recommend you head over to One Drop’s forums and search for the article named “The Evolution of the Project”. It is a fun read with some amazing shots of the early prototypes.