3Yo3 Omnicron

Reviewed by Jared Alperin

Introduction

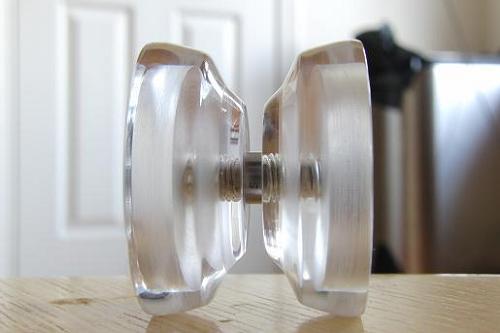

Landon Balk’s work is truly something special. Every yoyo produced by his small company is made entirely by hand on his lathe. No computer input, just the skill of his hand. I always find it amazing that in a market filled with automated lathes and milling machines, Landon is able to retain the high level of precision and consistency I’ve experienced in all of his yoyos. 3Yo3’s previous releases have generally been critiqued of not having enough spin time to get through the long and complicated tricks of the modern yoyo world. Landon decided it was time to change that, and thus the Omnicron was born; H-shaped, with material cut out from the sides to provide as much rim-weight as possible.

One of the best parts about buying a yoyo that is made to order is the role you get to play in its creation. You can decide what color, finish, and bearing size you prefer. I’ve had the opportunity to try two different versions of the Omnicron. The first is clear, polished, with an A-sized bearing. The second is bead blasted, giving it a frosted look, with a D-sized bearing.

Specs

- Diameter – 52.07mm

- Width 40.64 mm

- Weight- 70 grams

- Bearing size – Your choice!

- Gap Size – Around 4mm, but dependent on the bearing size.

- Response – 3.15/2.02 mm silicone groove. Also accepts YYJ Silicone pads (O-ring sized)

Construction

I’m not sure whether Landon has any plans for packaging, but mine came wrapped up in newspaper, which is functional but not exactly fitting for the beauty of these yoyos. The Omnicron tends to look much larger than it actually is. This may be because of the H-shape, which makes the rims look absolutely gigantic. The Omnicron is the first of 3Yo3’s line to feature threaded inserts with a smaller axel. This will prevent the axel from stripping the acrylic as many had worried it would with Landon’s older models. Landon has also gone to the trouble of hand tuning each yoyo and securing one side of the axle with teflon tape to keep them smooth and balanced. The bearing sits on metal spacers for increased durability, as well as lower friction. It feels that Landon has really taken advice on his old models, and has gone to every extent to make sure that this model is as great as it can be.

Weight

The distribution on the Omnicron is excellent, and meets a nice balance of rim weight + center weight for long spins without reducing playability. In my opinion, the Omnicron feels a little heavy for its size and shape. It sometimes feel downright rock-like during certain tricks, and has even torn skin off my finger after an especially hard throw. It’s not necessarily a negative, but it is definitely heavier than I would usually prefer.

Response and Bearing

The Omnicron comes with flowable silicone installed. The recess is nice and deep, causing the silicone to last for long periods. Both of my Omnicrons bind very snappy, without grabbing the string during play. My one complaint is that the only option for a pad replacement is the yoyojam pads, which are still a bit small in this recess. Flowable silicone isn’t for everyone, and the Omnicron could have sported more of a flow groove sized recess and retained the same perfect response it has now.

All of the bearings provided by Landon are stainless, seem very durable, and perform great. I’ve found they get a bit noisier than some other brands after a while, but de-shielding and throwing in a bit of lube fixed them instantly. The D-sized bearing in particular is a great performer. I actually found it preferable to any other D-sized bearing I’ve used in the past, including SPYY’s stock bearings, as well as KK’s.

Playability

The Omnicron was certainly successful in accomplishing its goal. It can easily obtain spin times on par with any aluminum yoyo in my collection. It’s always surprising how smooth these are; they have just a tiny bit of vibe (which may very well be tunable), and are much smoother than many aluminum yoyos on the market. Acrylic is absolutely beautiful mid spin, especially in the sunlight. Every throw is a reminder that I’m throwing a functional piece of art. The catch zone can be a little awkward at first, but I was used to it after the first hour or so of playtime. One downside of acrylic is how grippy it is on grinds. The non-bead blasted version is essentially not grindable. The bead-blasted version is a large improvement, but the Omnicron actually has an awkward shape for most grinds. Finger grinds cause too much friction due to the surrounding surface area, arm grinds are awkward due to the mid-sized H-shape, and thumb grinds are very difficult because of how short the cut in the sides is. Basically, if grinding is a necessity to you in a yoyo, this is probably not the one for you.

Honestly, there is also something a little lacking in the performance of acrylic (at least thus far). It doesn’t have that special something that aluminum has. It may have to do with the thinner walls that metal allows during design, or perhaps something to do with the nature of the material, but it always feels a little awkward. I find that the beauty of the material in the sun makes up for this small negative in the play, but that may not be true for others. In any case, it is a large improvement on the previous models of 3Yo3, and hopefully a sign that acrylic will continue to grow and exist in the community.

Final Thoughts

Everyone needs to throw a 3Yo3 at least once. They’re unique, highly playable, and absolutely stunning works of art. While they may not be on quite the same level as many aluminum lines in terms of play, they stand out in many other ways that fit them into their niche in the yoyo world. The Omnicron has once again stepped up the bar for this material, and has left me eager in anticipation of what Landon will come up with next.